Next generation lasers for semicon, lithography and holography

The future of high-tech innovation in fields such as semiconductor metrology, holography, and photolithography relies heavily on advancements in laser technology. These applications demand lasers that offer exceptional precision, stability, and reliability. TOPTICA Photonics provides multiple next generation single-frequency laser solutions that not only meet the stringent demands of these applications but also offer lower cost of ownership, making us the ideal partner for driving future innovations in these cutting-edge fields.

Key features & benefits

- UV / RGB laser with watt-class output power

- High efficiency, low Cost of Ownership

- High coherence: > 100 m coherence length (< 1 MHz linewidth)

- Excellent stability & reliability

- Easy, hands-off operation

Explore laser choices by application or specification

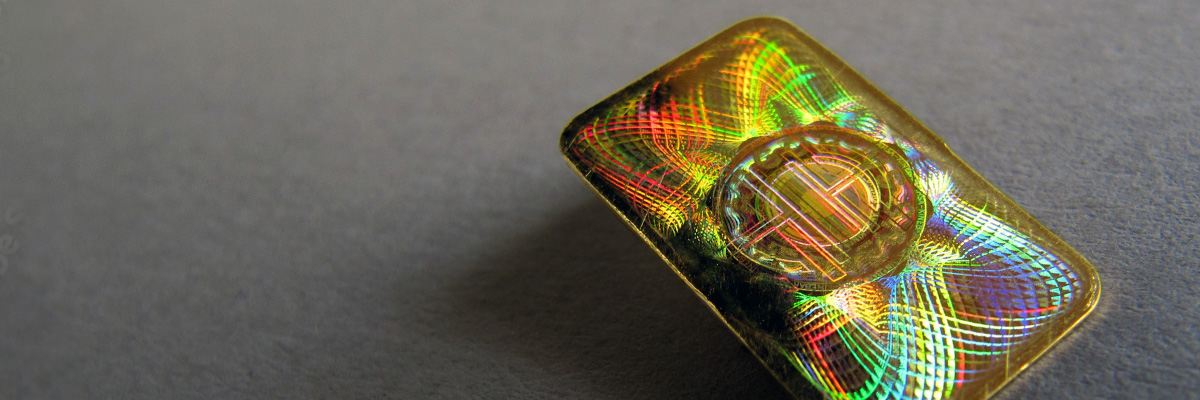

The use of laser holography has come a long way, since it started in the 1960s. Unlike traditional holograms with a fixed image, today's holographic applications are diverse, extending from security holograms on banknotes and passports to the creation of holographic optical elements (HOEs) for AR/VR headsets.

| Laser requirements | Customer benefits |

|---|---|

| RGB/VIS wavelength (440 - 660 nm) | White light holograms |

| Wavelength tuning option | Match recording wavelength to illumination spectrum |

| Long coherence length | High pattern contrast |

| High output power | short exposure time large exposure area |

| High power stability | High yield at high process speed |

| Wavelength accuracy & stability | Reproducibility |

Matching lasers

| System | Key wavelengths | Max. output power |

|---|---|---|

| ALS-VIS series | 488 nm / 514 nm / 532 nm | 2 W / 8 W / 10 W |

| DLC TA-SHG pro with tuning option | 445 … 470 nm* 520 … 535 nm* 615 … 640 nm* | Up to 1 W |

* Typical tuning range within the given center wavelength range: 10 nm

Interference lithography and holography share several similarities, as both techniques rely on the principles of light interference to create patterns or structures on a photosensitive material. But while the interference pattern in holography encode the phase and amplitude information of light, which can represent basically any 3D image or object, the pattern in interference lithography typically form periodic structures, such as lines, grids, or dots. This method is widely used in the production of nanoscale and microscale structures, e.g. diffraction gratings or optical filters.

| Laser requirements | Customer benefits |

|---|---|

| "Short" wavelength (violet - DUV) | Higher resolution, enabling the production of finer patterns |

| Long coherence length | High feauture contrast |

| High output power | Process speed, large area imaging |

| High power stability | High yield at high process speed |

| Wavelength accuracy & stability | Reproducibility, stable interference pattern |

Matching lasers

| System | Key wavelengths | Max. output power |

|---|---|---|

| TopWave 405 | 405 nm | 1 W |

| TopWave DUV | 229 nm / 257 nm / 266 nm | 10 mW / 15 mW / 300 mW |

| DLC TA-SHG pro | 365 nm, 390 nm | Up to 1 W |

| DLC TA-FHG pro | 193 nm, 213 nm, 244 nm, 257 nm | Up to 300 mW |

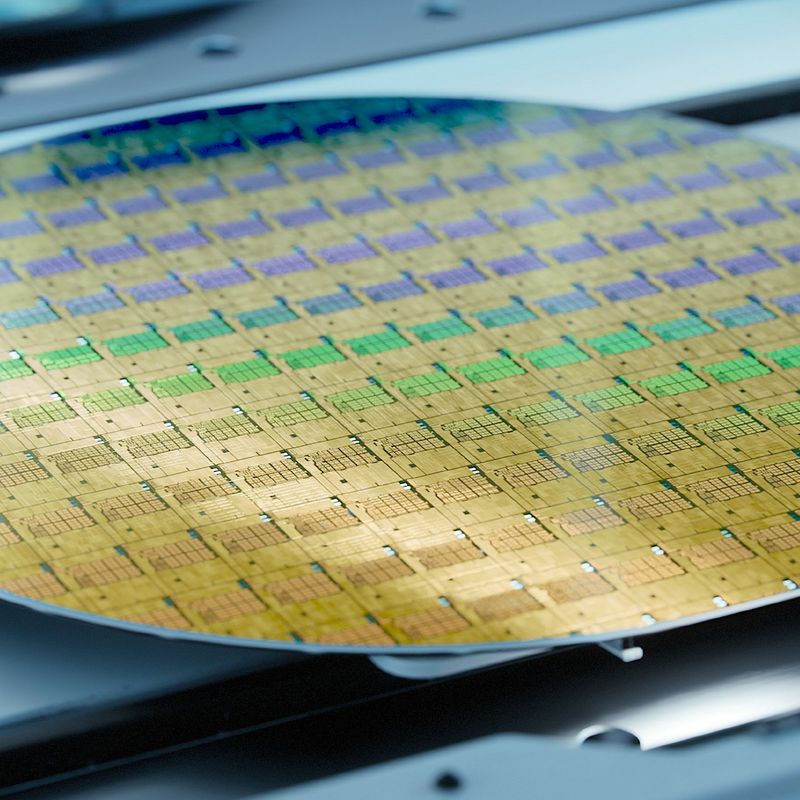

Mature semiconductor nodes are vital in the chip manufacturing process due to their cost-effectiveness, reliability, and suitability for a wide range of applications (e.g. IoT devices). It all starts with the right laser source if you want to achieve those attributes with your microlithography tool or photomask writer.

| Laser requirements | Customer benefits |

|---|---|

| "Short" wavelength (violett - DUV) | Higher spatial resolution, small feature size |

| High output power | Increased process speed |

| High power stability | High yield at high process speed |

| Low noise | Reproducibility |

| Stable pointing | Resolution |

Matching lasers

| System | Key wavelengths | Max. output power |

|---|---|---|

| TopWave 405 | 405 nm | 1 W |

| TopWave DUV | 229 nm / 257 nm / 266 nm | 10 mW / 15 mW / 300 mW |

| iBeam smart | 375 nm, 405 | Up to 0.45 W |

| DLC TA-SHG pro | 365 nm, 390 nm | Up to 1 W |

Gas lasers have been an integral part of the semiconductor industry since its beginnings. But the industry, which is at the forefront of technological innovation, faces a pressing challenge: decarbonizing its value chain. The integration of diode and fiber laser technology offers a clear and simple path to reducing carbon emissions and improving sustainability. These advanced laser systems deliver precise, efficient and energy-saving performance, ensuring a reliable supply for decades to come.

| Wavelength | Legacy gas laser | Suggested replacement laser | Available wavelength | Max. output power |

|---|---|---|---|---|

| 647.1 nm | Kr+ Laser | DLC TA-SHG pro DLC RFA-SHG pro | 635 nm .. 650 nm | 1 W 6 W |

| 632.8 nm | HeNe | iBeam smart WS DFB pro | 633 nm, 638 nm 633 nm | up to 120 mW 10 mW |

| 514.5 nm | Ar+ Laser | ALS-VIS series | 514.5 nm | 8 W |

| 488.0 nm | Ar+ Laser | ALS-VIS series | 488 nm | 2 W |

| 457.9 nm | Ar+ Laser | DLC TA-SHG pro | 450 nm .. 470 nm | up to 1.3 W |

| 413.1 nm | Kr+ Laser (h-line) | TopWave 405 | 405 nm (413 nm) | 1 W (0.7 W) |

| 406.7 nm | Kr+ Laser (h-line) | TopWave 405 TopMode | 405 nm | 1 W 100 mW |

| 363.8 nm | Ar+ Laser (i-line) | DLC TA-SHG pro | 365 nm | 50 mW |

| 264.4 nm | Ar+ Laser SHG | TopWave DUV | 266 nm | 300 mW |

| 257 nm | Ar+ Laser SHG | TopWave DUV DLC TA-FHG pro | 257 nm | 15 mW Up to 200 mW |

| 244 nm | Ar+ Laser SHG | DLC TA-FHG pro | 244 nm | Up to 200 mW |

Semiconductor inspection and semiconductor metrology are two crucial processes in semiconductor manufacturing. While inspection aims to detect defects and ensure the wafer is free from contamination and other physical anomalies, semiconductor metrology focuses on measuring the exact dimensions and properties of semiconductor features to ensure they meet design specifications. Optical inspection (e.g. brightfield and darkfield microscopy) and metrology techniques (e.g. ellipsometry or scatterometry) rely on high-precision, low-noise laser system across an extended wavelength range spanning from the DUV to the NIR.

| Laser requirements | Customer benefits |

|---|---|

| DUV/VIS/NIR wavelength | Matching wavelength for measurement task, e.g. DUV wavelength for increased resolution |

| Low noise | Best signal to noise ratio |

| Wavelength accuracy & stability | Reproducibility |

| Long lifetime | Low cost of ownership, sustainability |

Matching lasers

| System | Key wavelengths | Max. output power |

|---|---|---|

| iBeam smart | 375 nm .. 850 nm | Up to 450 mW |

| iBeam smart WS | 633 nm, 638 nm, 785 nm, 808 nm, 828 nm, 850 nm | up to 120 mW |

| DFB pro | 633 nm, 780/785 nm, 852 nm | up to 120 mW |

| TopWave DUV | 229 nm / 257 nm / 266 nm | 10 mW / 15 mW / 300 mW |

| DLC TA-FHG pro | 193 nm, 213 nm, 244 nm, 257 nm | Up to 300 mW |

| System | Key wavelengths | Max. output power | Linewidth (typ.) |

|---|---|---|---|

| ALS-VIS series | 488 nm / 514 nm / 532 nm | 2 W / 8 W / 10 W | < 0.5 MHz |

| Top Mode | 405 nm | 100 mW | < 5 MHz |

| TopWave 405 | 405 nm | 1 W | < 25 MHz |

| TopWave DUV | 229 nm / 257 nm / 266 nm | 10 mW / 15 mW / 300 mW | < 1 MHz |

| DLC TA-SHG pro with tuning option | 445 … 470 nm* 520 … 535 nm* 615 … 640 nm* | Up to 1 W | < 0.5 MHz |

| DLC TA-SHG pro | 365 nm, 390 nm, 405 nm, 560 nm, 633 nm | Up to 1 W | < 0.5 MHz |

| DLC TA-FHG pro | 193 nm, 213 nm, 244 nm, 257 nm | Up to 300 mW | < 1 MHz |

| DFB pro | 633 nm, 780/785 nm, 852 nm | up to 120 mW | < 2 MHz |

| iBeam smart WS | 633 nm, 638 nm, 685 nm, 785 nm, 852 nm | up to 120 mW | < 25 MHz |

| iBeam smart | 375 nm .. 850 nm | up to 450 mW | 0.5 nm |

* Typical tuning range within the given center wavelength range: 10 nm