Precision Microfabrication

Microfabrication with femtosecond lasers

Laser microfabrication uses focused laser light to locally remove, modify, or structure material. When a laser pulse hits the surface, its energy is absorbed and converted into heat or plasma, leading to melting, evaporation, or structural change.

With ultrafast lasers — emitting pulses shorter than a few picoseconds — this interaction happens faster than thermal diffusion. The result is athermal or “cold” ablation, where material is ejected before heat can spread, leaving the surrounding area unaffected. This makes femtosecond processing uniquely suited for applications requiring nanometer precision and minimal collateral damage.

Femtosecond vs. picosecond processing

| Characteristic | Femtosecond laser | Picosecond laser |

|---|---|---|

| Pulse duration | < 1 ps | 1 - 10 ps |

| Ablation mechanism | Non-thermal, multiphoton ionization | Partial thermal contribution |

| Edge quality | Ultra-clean, burr-free | Slightly more melting |

| Material flexibility | Works even on transparent materials | Mostly absorbing materials |

| Processing precision | < 100 nm achievable | Sub-micron |

| Throughput | Lower (per pulse), higher quality | Higher (per pulse), lower edge fidelity |

Femtosecond lasers are preferred when extreme precision, minimal debris, or damage-free surfaces are required — for example, in semiconductor scribing, transparent material machining, and micro-optics production.

Picosecond lasers, on the other hand, offer a good compromise between processing speed and quality, making them ideal for industrial throughput and cost-efficient manufacturing.

Application areas

Semiconductor & electronics

In the semiconductor industry, femtosecond lasers enable microscale patterning, via drilling, wafer dicing, and thin-film ablation with minimal thermal stress. Their ultrashort pulses allow clean cutting of fragile materials such as sapphire, GaAs, or SiC without introducing microcracks.

They are also key tools for selective layer removal and repair of transparent films in display manufacturing and flexible electronics.

For next-generation semiconductors, femtosecond micromachining supports 3D structuring, photonic interconnects, and quantum photonic chip fabrication — processes that would be impossible with conventional thermal machining.

Medical & life sciences

In the medical field, ultrafast lasers have become synonymous with precision and safety. Femtosecond pulses are used for corneal surgery (LASIK, SMILE), microfluidic channel fabrication, biocompatible implant structuring, and lab-on-a-chip manufacturing.

Because the interaction is non-thermal, biological tissues or polymers can be cut or modified without burning or collateral damage, enabling new kinds of minimally invasive procedures and biomedical devices.

Optics & photonics

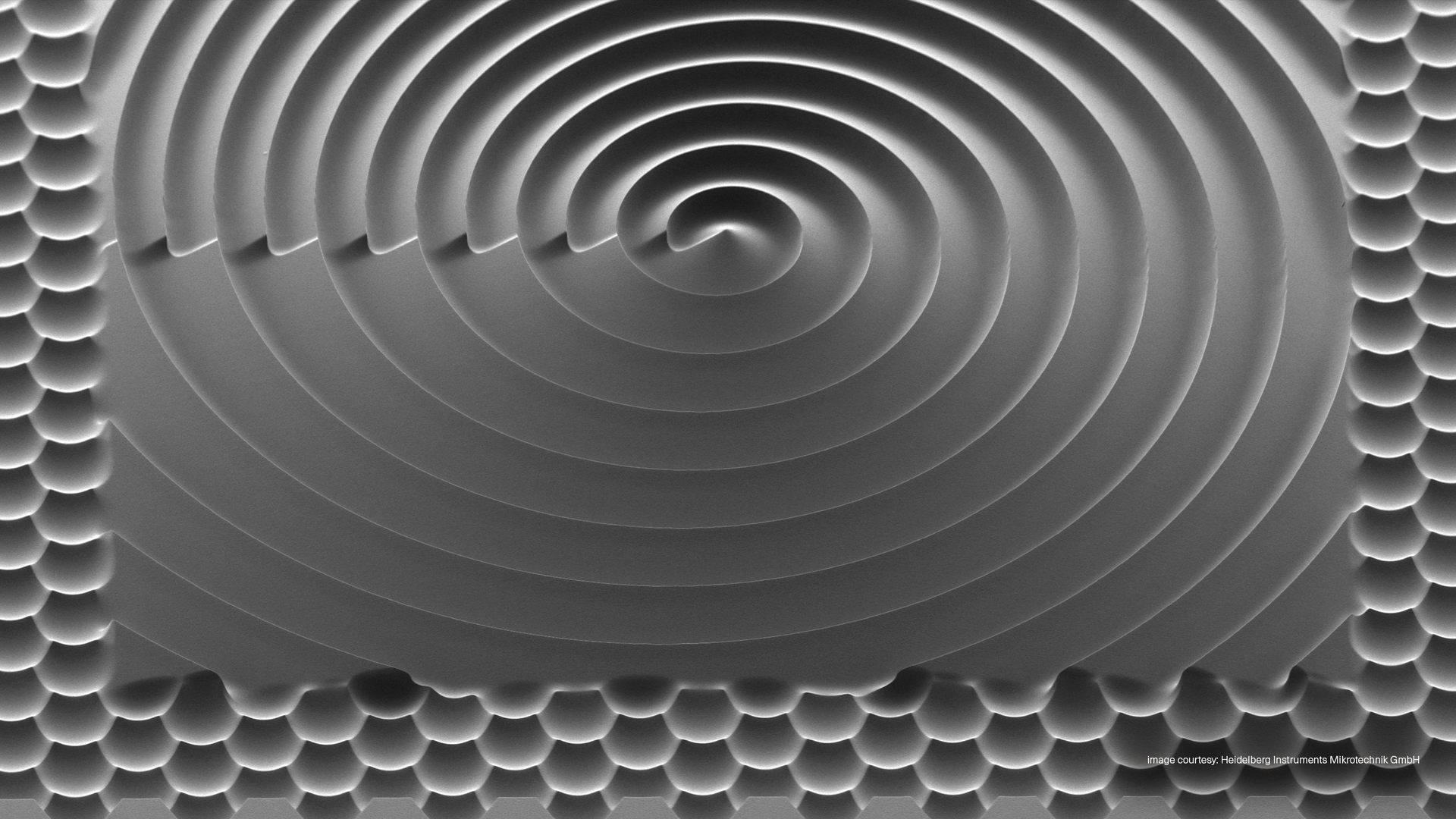

Optical component manufacturers rely on femtosecond lasers for waveguide writing, fiber Bragg grating inscription, diffractive optics fabrication, and surface functionalization. The nonlinear interaction of ultrashort pulses enables direct refractive-index modification inside transparent materials, producing true 3D photonic structures — such as integrated interferometers, couplers, and micro-lenses.

Automotive & mobility

In automotive and e-mobility industries, laser micromachining supports the production of high-reliability sensors, battery components, and micro-injectors. Femtosecond and picosecond lasers provide burr-free cutting of thin metals and ceramics, as well as precise drilling of fuel nozzles or cooling holes in turbine components.

As vehicles become smarter and more electrified, ultrafast laser processing ensures both miniaturization and robustness of critical components.

The importance of fiber-based seeders

Modern high-power industrial lasers are typically master-oscillator power-amplifier (MOPA) systems. At their core lies the seed laser — a compact, low-power oscillator in the mW regime that defines the pulse characteristics, timing, and spectral quality of the entire system.

Fiber-based femtosecond and picosecond seeders offer decisive advantages:

- Excellent beam quality (M² ≈ 1) for precise focusing

- Low noise and high stability for consistent processing results

- Compact, rugged design suitable for industrial environments and swap-in integration

- Synchronization capability for pump-probe or multi-laser setups

Because the seeder determines pulse duration, wavelength, and timing jitter, its performance directly translates into process quality and reproducibility.

Fiber technology also ensures long lifetime, maintenance-free operation, and easy integration into amplifier chains based on Yb-, Er-, or Tm-doped gain media.

Wavelengths for microfabrication — from UV to Mid-IR

| Wavelength | Typical source | Application highlights |

|---|---|---|

| 355 nm (UV) | Tripled Yb or Nd lasers | Fine structuring of metals, polymers, thin films; high resolution patterning |

| 532 nm (Green) | Frequency-doubled Yb lasers | Transparent material machining (glass, sapphire); micro-optics |

| 790–1030 nm (NIR) | Ti:Sapphire or Yb-fiber lasers | Universal material processing; wafer dicing; 3D structuring |

| 1064 nm (IR) | Tm- or Ho-fiber lasers | Emerging region: processing of polymers, semiconductors (GaN, Si), and biomedical materials |

The 2 µm wavelength region has recently gained attention for exotic seeders and new processing capabilities.

At this wavelength, absorption in many polymers and semiconductors increases, enabling gentle yet efficient ablation with reduced plasma shielding.

Tm- and Ho-based femtosecond seeders are opening new avenues for infrared micro-machining, THz generation, and even biomedical laser surgery, where water absorption at 2 µm offers precise depth control.

Benefits of ultrafast lasers in industry

- Athermal processing: No heat-affected zone, no recast, no microcracks.

- Universal material capability: Metals, dielectrics, polymers, ceramics, and transparent crystals.

- High aspect ratio structures: Drilling and cutting with near-vertical sidewalls.

- Micron-level accuracy: Enabled by diffraction-limited focusing and controlled energy deposition.

- Repeatability and automation: Ideal for integration into robotic and galvo-scanner systems.

- 3D structuring capability: Internal modification of transparent materials for photonics and life-science devices.

These characteristics make femtosecond lasers a key enabling tool for next-generation nanofabrication and precision manufacturing.

Examples paving the road to next-generation technology

- 3D Photonic Chips: Femtosecond laser writing creates integrated waveguides and couplers inside glass, forming the backbone of quantum photonics and optical computing.

- Flexible OLED Displays: Picosecond lasers structure transparent conductive films with sub-micron precision, allowing thinner, bendable displays.

- Implantable Micro-Sensors: Femtosecond pulses pattern bio-compatible materials without contamination, enabling next-gen health monitoring.

- Wafer-Level Packaging: Precise through-silicon vias and dielectric ablation support advanced heterogeneous integration.

- Aerospace & Automotive Components: Clean drilling and surface texturing improve adhesion, cooling, and friction performance in lightweight designs.

Conclusion

Femtosecond laser microfabrication represents the pinnacle of precision manufacturing. Its combination of ultrashort pulse duration, spatial control, and flexibility across materials delivers unmatched quality and minimal thermal impact.

When paired with modern fiber-based seeders — whether at 1030 nm for universal machining or in the emerging 2 µm region for specialized applications — ultrafast lasers become powerful enablers of progress across semiconductor, medical, optical, and automotive industries.

As device dimensions shrink and design complexity grows, femtosecond laser microfabrication continues to redefine what is possible — one pulse, one micron, and one idea at a time.