Plastic Inspection

A new vision through plastics

Plastics and polymers are everywhere: in packaging, automotive components, medical devices, and consumer goods. Yet their versatility also poses a challenge: different materials, fillers, and multilayer combinations make non-destructive quality inspection difficult. Conventional optical and infrared methods often fail, since many plastics are opaque or highly scattering in those wavelength ranges.

Terahertz (THz) inspection provides the solution. Operating between the microwave and infrared domains (0.1–10 THz), THz radiation penetrates most non-conductive materials and provides submillimeter-scale structural and thickness information, without contact or sample preparation.

THz systems “see” what optical sensors cannot, making them the tool of choice for reliable, in-line and laboratory analysis of plastic materials and composite structures.

Principle: Time-domain terahertz spectroscopy

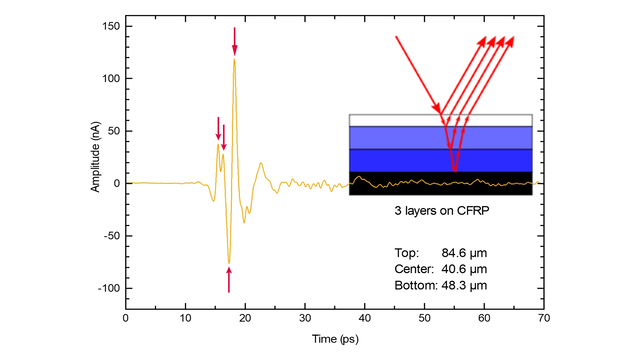

In a pulsed THz system, ultrashort laser pulses generate broadband THz transients, which are directed onto the sample. Each material interface, between adjacent layers or a plastic structure and air, reflects a part of the THz pulse. By recording the returning echoes as a function of time, the system reconstructs a depth profile of the internal structure.

The principle is analogous to radar, but on a microscopic scale: the time delay between reflections directly corresponds to layer thickness, while the amplitude and phase of the reflected signal reveal refractive index and absorption characteristics.

Why a broad THz signal matters

Resolution and accuracy in THz inspection are fundamentally linked to the bandwidth of the THz pulse. A wider frequency range corresponds to a shorter pulse in the time domain and thus, a sharper response to each interface.

Broadband pulses (up to 5 THz, corresponding to sub-picosecond durations in the time domain ⭢ (4-6 THz ...)) enable fine depth resolution, and can thus distinguish interfaces spaced only a 5-10 micrometers apart, depending on the material’s refractive index. Narrowband signals, in contrast, would blur adjacent layers.

TOPTICA’s THz-TDS systems TeraFlash pro and TeraFlash smart are especially powerful for plastics inspection. By generating ultrashort, high-dynamic-range THz pulses, they provide the precision needed to measure layer thicknesses accurately, identify delaminations, and verify film homogeneity.

Fast and robust: ECOPS for Industrial Environments

Industrial inspection environments are rarely quiet. Vibrations, acoustic noise, and air turbulence can easily distort long measurement cycles. To overcome these challenges, modern THz systems employ Electro-Optic Coherent Sampling (ECOPS), a high-speed acquisition method developed for robustness and efficiency. The ECOPS scheme lies at the heart of TOPTICA's system TeraFlash smart.

With ECOPS, THz signals are sampled at kilohertz (kHz) rates, allowing:

- Real-time measurement even of moving samples (e.g. on conveyor belts).

- Reduced sensitivity to mechanical perturbations, as the fast sampling “freezes” vibrations.

- High throughput, which is essential for 24/7 inline inspection and quality assurance.

ECOPS enables full waveform acquisition within milliseconds, allowing automated inspection at production speed.

What THz reveals in plastics

By analyzing both amplitude and time delay of the reflected THz signal, application specialists can extract key material parameters:

- Layer thickness: direct measurement through time-of-flight differences between reflections.

- Refractive index: determined from the optical path length and material delay.

- Material composition: absorption signatures can help to identify polymer materials.

- Defects: delamination, voids, and inclusions appear as additional or distorted reflections.

- Moisture content: reveals itself by its broadband attenuation of the transmitted THz signal.

THz inspection thus accomplishes non-destructive measurements, valuable for both R&D laboratories and industrial process monitoring.

Advantages over conventional methods

Conventional non-destructive Methods include ultrasonic measurement, optical and infrared analysis and X-ray/Beta/Gamma Gauging

| Property | THz inspection | Convential techniques |

|---|---|---|

| Penetration | Works on opaque plastics | Limited to transparent films |

| Resolution | < 5 µm (with broadband pulses) | typically 10–50 µm (optical/ultrasonic) |

| Non-destructive | ✓ contact-free | Often destructive sampling |

| Multilayer capability | ✓ simultaneous measurement | ✗ sequential or indirect |

| Speed | kHz-rate possible (with ECOPS) | slow mechanical scanning |

| Safety | Non-ionizing radiation | may involve X-rays or chemicals |

Conclusion: Quality through clarity

Terahertz technology offers a unique window into the interior of plastic materials: contact-free, fast, and precise. By combining broadband spectral content for sub-millimeter resolution, kHz-rate ECOPS acquisition rates and architectures adapted to industrial environements, THz systems deliver unmatched capability for non-destructive plastic inspection.

THz makes quality visible, even where light cannot penetrate.