Pulsed Terahertz Systems for Paint and Coating Layers

Assessing layer thickness with terahertz pulse echoes

- Terahertz pulses assess the thickness of thin layers and multi-layer systems

- Each layer interface reflects a part of the terahertz pulse

- Broad terahertz bandwidth translates into high resolution

- Measurements in reflection and transmission geometry

- Recommended system: TeraFlash pro, TeraFlash smart

Different fields of applications for contact-free thickness measurement

Contact-free thickness measurements play an increasingly important role in industrial process monitoring and quality control. In automotive manufacturing, the exact thickness of paint and coating layers plays a crucial role not only for the overall appearance, but also for protection against UV radiation and corrosion. In pharmaceuticals, the coating thickness governs the release of the drug inside the body, with consequences on the efficacy and potential side effects. In chip production, highly homogeneous polymer coatings act both as protection against moisture and dust and as stress absorbers.

Special features of terahertz pulses

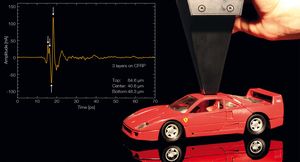

Most of the traditional thickness gauges require physical contact to the layer under test, and fail in case of non-metallic substrates. Terahertz pulses, by contrast, resolve the thickness of each individual layer, as long as adjacent coatings differ in their refractive index. Non-contact measurements in transmission or reflection geometry can even monitor drying or curing processes of wet coatings. The analysis combines time-of-flight measurements of terahertz pulse echoes with elaborate data post-processing, which involves Fourier transformations and advanced fitting routines. This method has proven successful: TOPTICA’s customers have achieved thickness measurements down to 20 µm, with accuracies on the single-micron level.

See more in our product videos:

-

Related Products

-

Related Applications

-

Related Literature

Related Literature

- Review paper: Naftaly, M., et al., Industrial applications of terahertz sensing: State of play, Sensors (2019)

- Publication: M. Yahyapour et al., Fastest thickness measurements with a terahertz time-domain system based on electronically controlled optical sampling; Appl. Sciences (2019)

- Conference Abstract: Yahyapour et al., Non-Contact Thickness Measurements with Terahertz Pulses, WCNDT 2016

- Publication: N. Vieweg et al., Terahertz-time domain spectrometer with 90 dB peak dynamic range; J Infrared Milli. Terahz. Waves 35:10 (2014)

- Article: M. Lang et al., Laser-based terahertz generation & applications, Photonik International (2014)

- Downloads